PRODUCT INFORMATION

Solid Hardwood Flooring | Product Information

B 5.0

B 5.0

PRODUCT DESCRIPTION

Junckers 20.5 mm solid hardwood planks are factory finished and ready to install in accordance to Junckers Laying Instructions.

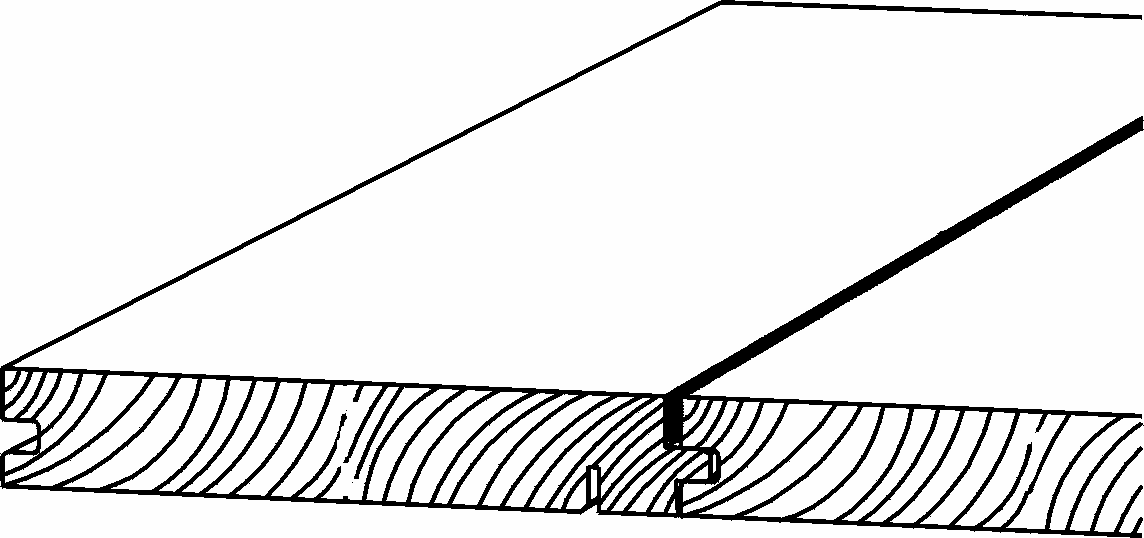

Each plank is made as one floor board and provided with a bevelled edge of approx. 0.5 mm. Each plank is tongued and grooved on all four sides.

Fig. 1

PRODUCT DATA / TOLERANCES

Nominal Plank Dimensions Thickness: 20.5 mm (±0.2 mm) Width: 140.0 mm (±0.2 mm) Length: 3000* / 2700* / 2400 / 2100 / 1800 / 1500 / 1200 / 900 / 600mm (±1.0 mm).

* Not Black Oak

Drying Method

The planks are kiln dried.

Moisture Content

Oak and ash planks are supplied with an average moisture content of 8% (±2%).

Black Oak planks are supplied with an average moisture content of 9% (±2%).

Precision Engineering

Landing Deviation: 0.2 mm (0.3 mm in localised areas). The plank ends are right angled at ±0.3mm.

PRODUCT RANGE

| Product / Product name | Grades | Surfaces | Variants |

| Oak | Classic Harmony Variation | Ultra matt lacquered Silk matt lacquered Oil Untreated Textured Textured and/or coloured** | Ships decking* |

| Oak Nordic | Classic Harmony Variation | White pigmented and Ultra matt lacquered | Ships decking* |

| Oak Pearl | Harmony | Metallic-pigmentered and Ultra matt lacquered | Ships decking* |

| Black Oak | Harmony Variation |

Ultra matt lacquered Oil Untreated Textured and/or coloured** | Ships decking* |

| Dark Ash | Classic | Ultra matt lacquered Silk matt lacquered Oil Untreated | Ships decking* |

| Dark Ash Nordic | Classic | White pigmented and Ultra matt lacquered | Ships decking* |

*All products are available as ships decking, see Fig. 2

**According to standard product range

Fig. 2

Specially designed foamed PVC strip with compact cells to absorb movements in hardwood floors. The dimension of the strip is 3x8 mm. Installed it provides a 2 mm wide “Ships Decking Joint”, which varies during the year according to changes in the relative humidity.

TECHNICAL PROPERTIES

Resistance to Indentation

All Oak- and Ash products: Approx. 3.4 Hardness Brinell

Slip Resistance, (preliminary):

Factory lacquered and oiled: Approx. 0.4 (DIN 18032/2)

Fire Classification, (DIN EN 13501-1): Cfl – S1

Thermal Conduction, (Transmission coefficient): Approx. 0.17 W/mK

Heat Resistance: Approx. 0.12 m² K/W

FACTORY SURFACE TREATMENT

Lacquered

Oak and Dark Ash:

Priming: Several coats of UV-light curing primer.

Top finish: Two-component polyurethane lacquer, silk- or ultra matt.

Total film thickness: Min. 40 µ.

Oak and Dark Ash Nordic:

Priming: Whitetoned stain.

Intermediate treatment: UV-light curing lacquer.

Top finish: Several coats of two-component polyurethane lacquer, ultra matt.

Total film thickness: Min. 40 µ.

Oak Pearl:

Priming: Water based transparent stain.

Intermediate treatment: Several coats of UV-light curing lacquer.

Top finish: Two-component polyurethane lacquer, ultra matt.

Total film thickness: Min. 40 µ.

Black Oak:

Pre-treatment: NH3-treatment to achieve the dark colour.

Intermediate treatment: Several coats of UV-light curing lacquer.

Top finish: Two-component polyurethane lacquer, ultra matt.

Total film thickness: Min. 40 µ.

Oiled

Priming: Surface saturation using oxidative drying urethane oil.

Top finish: Oxidative drying urethane oil.

Total oil consumption: Addition to a full surface saturation.

Untreated

Final sanding to grit 150.

PACKING AND WEIGHT

Wrapped in polythene. 6 boards / layers of boards in each bundle. 1 layer can include mixed length, using standard board lengths, see Fig. 1. Orders can include mixed lengths of packs.

Number of m² per pack according to package-length [mm]:

1500 / 1.26

1800 / 1.51

2100 / 1.76

2400 / 2.02

2700* / 2.27

3000* / 2.52

* Not Black

Oak Weight, kgs/m²:

All Ash products: 14.2

All Oak products: 14.7