GENERAL INFORMATION

Junckers Sports Floor Systems

Sport

D 1.0

D 1.0

Fig. 1

D 1.0 General Information

D 1.1 Clip System Information

D 1.2 Batten System Information Specifier’s Information Laying Instructions

INTRODUCTION

Junckers sports floors are based on 22 mm solid boards nailed to prefabricated resilient batten systems or laid as floating floors with the clip system or as portable floor system on a resilient underlay.

All Junckers sports systems fully conform to EN 14904.

The batten systems can be installed directly on to a screeded subfloor or levelled up, e.g. with Junckers patented wedge systems. Construction heights from 45 mm. Floating floors are laid on a screeded subfloor with a construction height of 27 or 32 mm, depending on the underlay.

Fig. 1 shows the layout of the Junckers Technical Information System concerning floors for sport.

Please note that full information on a floor system comprises the data in General Information, System Information, Specifier's Information and Laying Instructions.

An example of full information on a Junckers 22 mm clip system is D 1.0 - General Information, D 1.1 - Clip System Information, D 2.1 - Specifier's Information and D 2.1.1 - Laying Instructions.

LIABILITY

The information provided in the Junckers Technical Information applies to specification of building materials/components as well as functional aspects of floor structures which include Junckers boards.

Please note that Junckers Industrier A/S accepts no liability for functional characteristics of floor structures of which the materials or use deviate from the specifications, or of which the construction deviates from the directions given.

CLIMATE CONDITIONS

Junckers solid hardwood floors can be laid in humidity conditions ranging from 25 to 85 % relative humidity (RH). However in order to keep movement of the floor, due to changes in the humidity to a minimum, the humidity range should not vary more than 30 % RH across the year. Examples of humidity ranges are: 25‑50 %, 35‑65 % and 60‑85 % RH. In addition to this the relative humidity should be stable for extended periods of time during the year.

The humidity level of sports buildings, e.g. sports halls and gyms, is usually equivalent to the conditions in residential buildings, e.g. 35-65 % RH (UK). Parameters such as operating temperature and method of ventilation used during the year determine whether the humidity level can be maintained naturally or must be controlled in certain periods. Should deviations be expected, it is advisable to contact Junckers Technical Service Department.

BEFORE LAYING THE FLOOR

The building must be dry and weather tight. The heating system must be installed and tested, and during the heating season should be in operation. Cast concrete elements, including casting of sockets for e.g. net poles as well as plastering, screeding and other wet trades which can contribute moisture to the building, e.g. priming of paintwork, must also be completed.

Before materials are delivered the relative humidity of the building must be within the expected range for the building when in use, e.g. 35-65 % RH, and the temperature must be approx. 16-20° C (UK).

FLOOR-LAYING

Solid boards should always be laid immediately after arrival at the building. The packaging should first be opened just before laying begins.

On batten floors the boards are secret-nailed to the substructure in accordance with the 10‑board rule, which is based on the expected maximum relative humidity in the building during the year.

Clip system floors are laid as floating floors, and the clip size is determined according to the expected maximum relative humidity of the building during the year.

STIFFNESS AND LOADBEARING STRENGTH

Junckers sports floors are designed to provide good conditions for sporting activity and adequate load bearing strength for the expected loads on the floor surface in connection with sports activities.

The functional properties of the individual floor systems, especially their impact absorption and elasticity, depend on e.g. the structural design and are documented via tests in accordance with known standards.

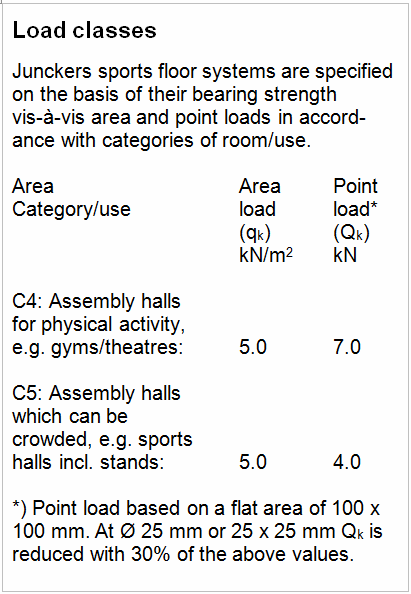

The floor systems’ bearing strength is stated in the Specifier’s Information for the individual floor systems and is related to the load classes in EN 1991-1-1, see Table 1. Trampolines or similar should be equipped with “shoes/feet’s” with a flat area of min. 200 x 200 mm to distribute the load. Please consult with Junckers for information relating to retractable seating, scaffold towers or scissor lifts.

The Specifier’s Information datasheets for the individual batten systems specify a board bond pattern which must be complied with exactly in order to achieve maximum bearing strength.

On specification it must be considered whether inappropriately high deflection can occur in connection with heavy loads, e.g. from mobile stands, which can reduce the floor and the tribunes functional capability. In that case the stiffness of batten floors can be increased, e.g. by installing extra battens and/or fixing of inelastic packing. For floating floors the resilient underlay can be replaced by a non-resilient underlay, e.g. plywood. If reinforcement is required in the playing zone it should be designed in a way where the elasticity of the floor is maintained.

In the case of extraordinarily high loads, e.g. exhibitions, etc., the bearing strength of the floor systems can be increased by overlaying the floor with additional load distributing sheets such as plywood.

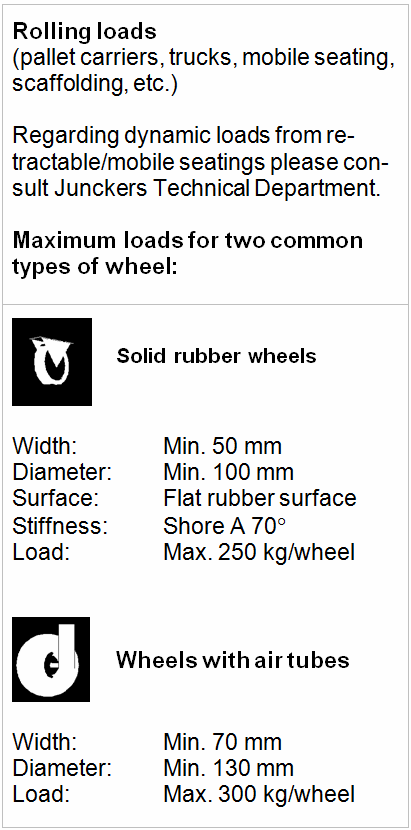

In addition to the loads stated in Table 1, loads can be imposed by rolling equipment. The Specifier's Information datasheets give information on rolling loads on floor systems. For specification of two common wheel types on rolling equipment, see Table 2.

Table 1

Table 2

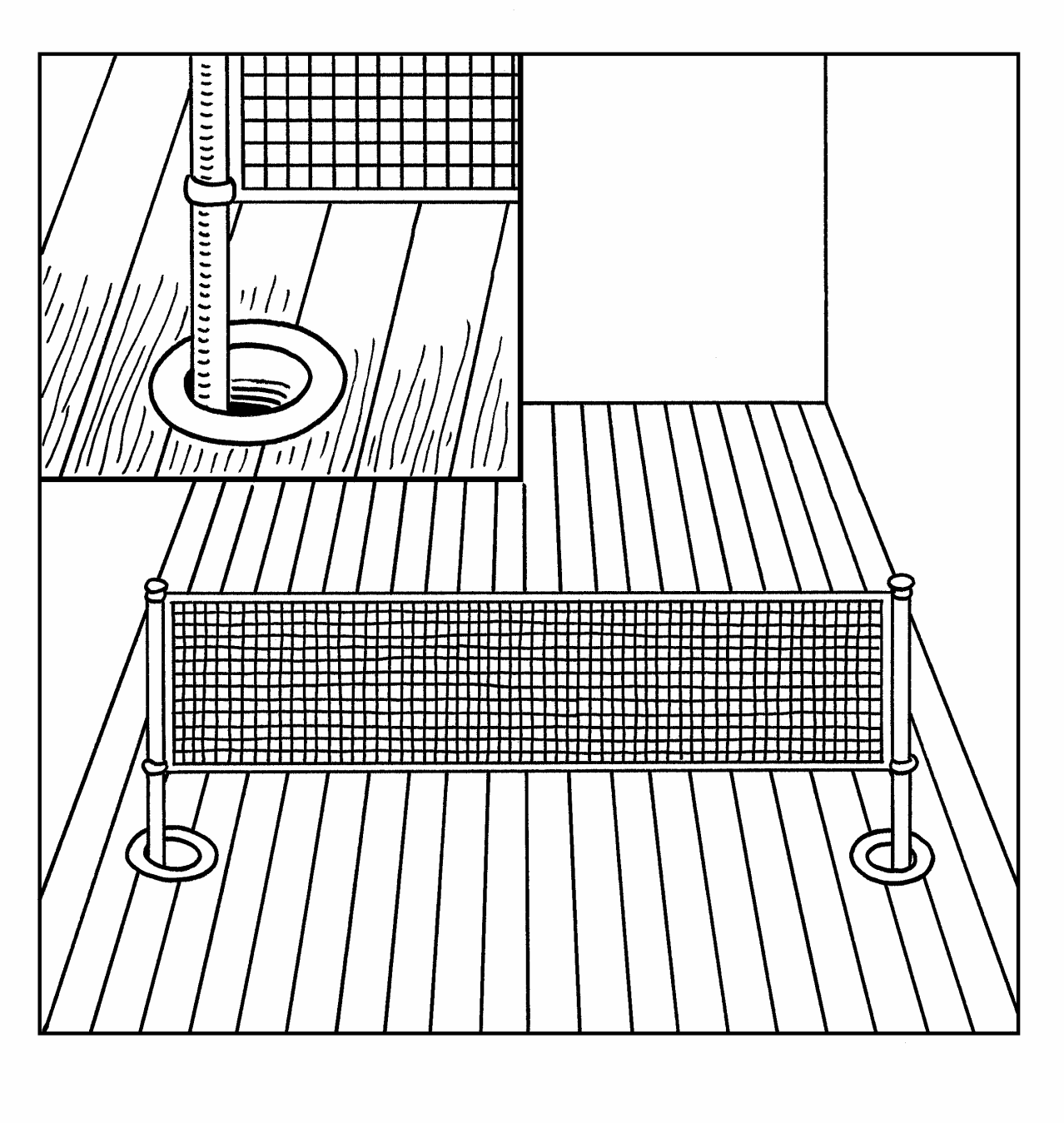

Fig. 2

FLOOR ROSETTES

Floor rosettes consist of a socket cast into the concrete subfloor, a flange mounted in the floor surface and a cover placed in the flange. The socket and flange must be installed so that both vertical and horizontal movement of the floor is unimpeded.

The internal diameter of the flange must exceed that of the pipe, i.e. the external diameter of the net pole, by at least 40 mm. At the outermost zones of the floor all flanges are mounted excentrically towards the middle of the floor in relation to the sockets in the concrete, see Fig. 2.

COVERING OF PARQUET FLOORS

It is not normally necessary to cover floors during the construction period. Should covering nonetheless be considered necessary, it should be with strong floor cardboard or similar which is not glued to the floor. In areas subject to special loads and exposure, e.g. corridors, this covering can be replaced by/or supplementedwith hard fibreboards or similar. See also G 1.0.

LINE MARKING AND LAQUERING

For marking out of courts Junckers line marking paint is used. It is available in white, yellow, red, blue, green and black, see F 8.1.

To protect line markings and provide extra protection against wear it is recommended to seal the floor with an extra coat of lacquer using Junckers sports lacquer on completion of the floor, see F 8.1 and F 8.2.

CLEANING AND MAINTENANCE

Day-to-day cleaning is carried out with anti static sweeping or a damp cloth.

For further cleaning a floor‑cleaning machine may be used, provided that the water is sucked up immediately and the water consumption is kept to a minimum, see G 1.0 and G 8.0.

SERVICE

For more than 80 years Junckers has provided extensive service.

Junckers Technical Service Department and our network of service- and sales consultants are available with advice and guidance before, during and after floor‑laying.