SPECIFIERS INFORMATION FOR JUNCKERS BATTEN SYSTEM

Solid Hardwood Flooring

Batten System Information

C 1.2.1

Fig. 1

C 1.0 General information

C 1.2 Batten System Information

C 1.2.1 Specifier's Information

C1.2.2 Laying Instruction

GENERAL DESCRIPTION OF FLOOR SYSTEM

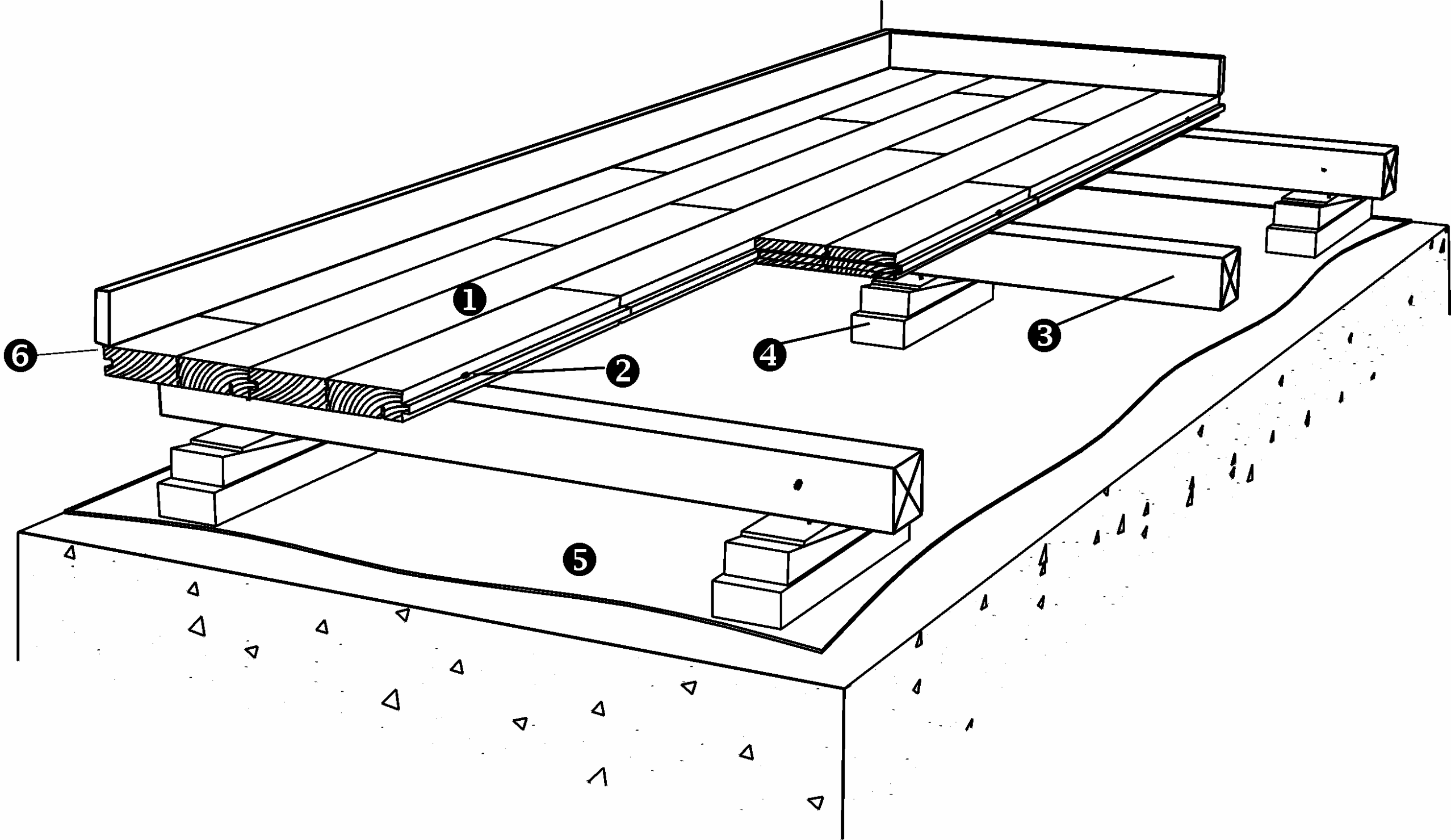

This floor system comprises Junckers solid 2-strip boards and planks, nailed to a traditional batten- or joist system.

The system is suitable for laying in both residential and commercial buildings, and can be laid in combination with underfloor heating systems, see E 4.0.

Please note that full information on a floor system comprises the data in C 1.0, C 1.2, C 1.2.1 and C 1.2.2. See Fig. 1.

SYSTEM SPECIFICATIONS

Junckers solid boards, nailed to battens or joists, are defined as loadbearing floors. The batten system comprises battens of minimum 36 x 50 mm, laid and levelled up on a firm subfloor. The joist system consists of whole timbers (square or approximated square cross-sections) of minimum 100 x 100 mm, half timbers or laminated timbers, and is used above ventilation spaces and cellars or as floor structures.

BATTENS AND JOISTS

Joists and battens may be of pine or spruce. The mean moisture content must be within the range of 6-12% and no individual measurement may be greater than 14%.

The moisture content is therefore expressed as max. 14%. Any impregnation fluid used on battens or joists must be dry before the floor is installed. Battens must be of a well-selected wood quality. Joists must also be of a well-selected wood quality and stress graded. For joists deeper than 100 mm the recommended moisture content should not fluctuate more than 2% from the measured mean moisture content, in order to avoid problems of uneven shrinkage of joists, resulting in creaking floors.

BOARDS

Boards are nailed to battens or joists according to a fixed 10-board rule, see C 1.2 - 10-BOARD RULE.

The boards are laid in a continuous pattern with irregular distribution of header joints. Header joints in the same span should not be closer than every third row. Stave joints in one row should not adjoin stave joints in an adjacent row, but must be spread as widely as possible

PACKINGS

The packing used for battens must be of a hard and dimensionally stable material such as plywood, combined with a soft board material, e.g. soft fibre-boards. Alternatively, plastic wedges may be used, either alone or in combination with the aforementioned materials.

If soft packing is used it is placed at the bottom of the packing: Soft packing is made of 12-13 mm thick soft 100 cm² size fibreboards, e.g. 125 x 80 mm, with a density of 225- 300 kg/m³, glued to at least 12 mm thick plywood. The packing is fixed to the battens with nails which should never reach down into the soft material or touch the concrete. If the packing is exclusively of soft material, it should be glued to the battens.

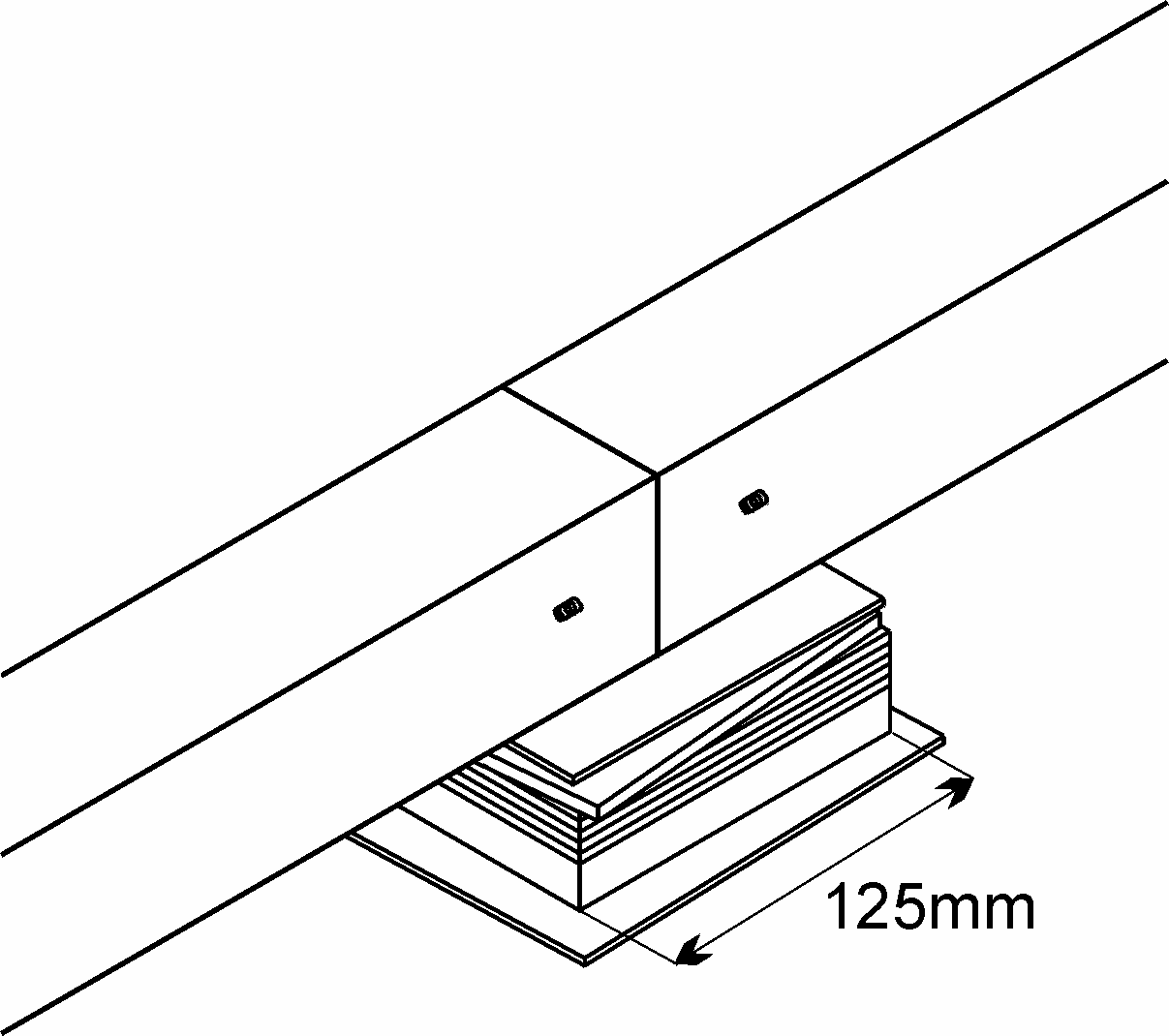

Batten joints may be supported by one single packing piece if the packing in the batten direction has a length of at least 125 mm, see Fig. 4. Batten joints must be staggered at least 600 mm to each other. These may only occur in straight lines where the batten ends are securely plate fixed together. At walls, etc. packing is placed a maximum distance of 100 mm from the batten ends.

On unscreeded concrete surfaces bitumen based felt under the packing is recommended. Using felt ensures that the packing is firmly placed and the felt also reinforces the moisture barrier, preventing moisture from seeping up into the packing material, which is exposed to a heavy load on unscreeded concrete.

Packing material for joists must be of hard and inelastic material, since the load is usually high. Where joists are laid against pillars, etc. a robust moisture barrier, e.g. bitumen based felt, must be placed at the bottom.

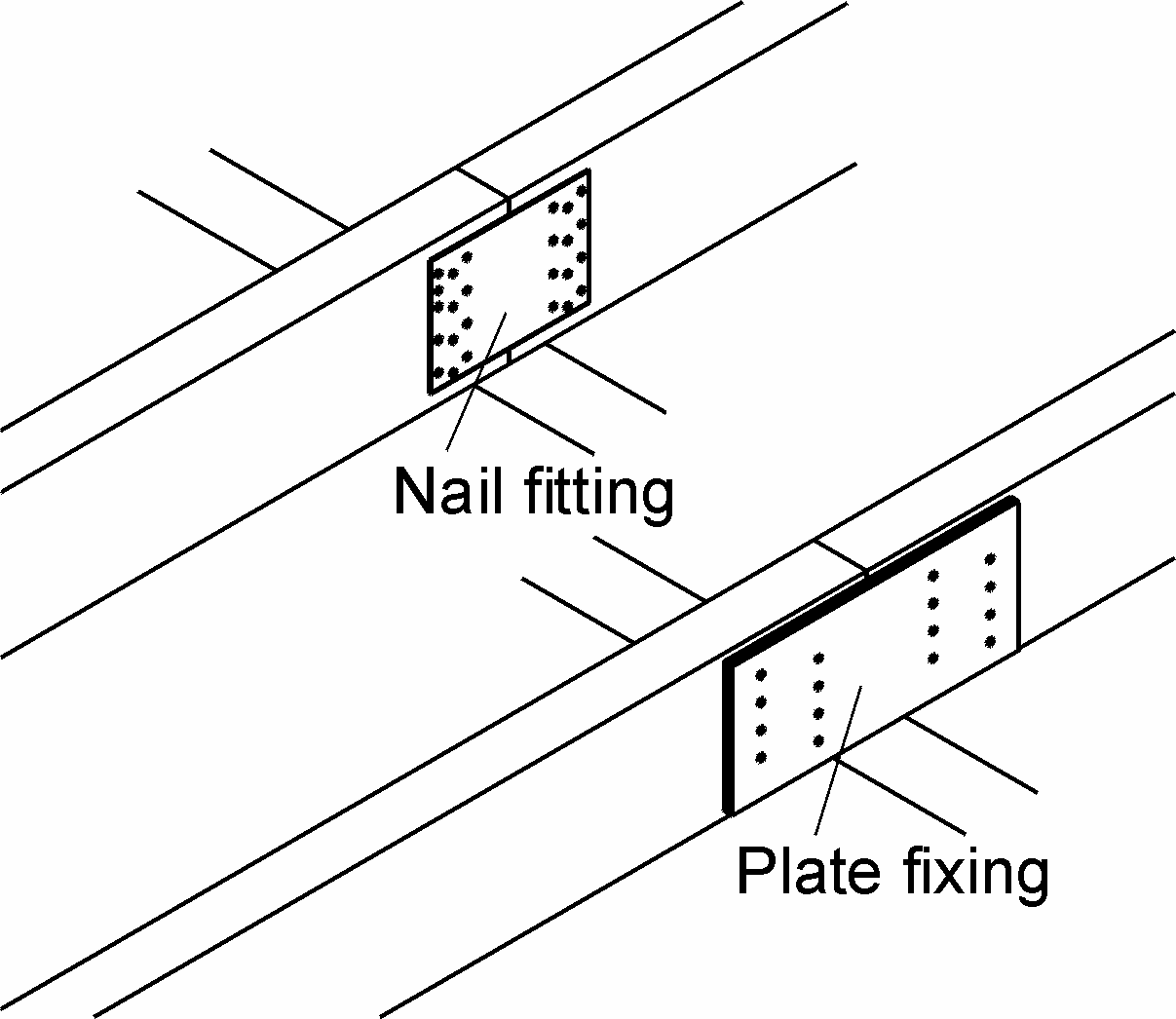

Joints between two joists must always be across a supporting structure and the two joist ends must be joined mechanically using plates or nail fittings, see Fig. 5.

Packing centres of battens and joists should be chosen according to the use of and expected load on the floor. Different categories are residential/office/light industry and assembly halls/shops, see C 1.2 - SPACING OF PACKINGS.

Fig. 4

Fig. 5

Fig. 2

COMPONENTS

1 - Boards

• Junckers 22 mm 2-strip boards, incl. shipsdecking

• Junckers 20.5 mm Planks, incl. shipsdecking.

Wood species, dimensions, grades and finish:

22 x 129 mm Solid 2-strip: see B 2.0

20.5 x 140 mm Planks: see B 5.0

20.5 x 185 mm Planks: see B 6.0

2 - Nails

• 2.2 x 45 mm Junckers J-Nails

• 2.6 x 65 mm T-nails (machine nails)

• 2.8 x 65 mm lost-head wire nails

3 - Battens or joists

4 - Packing

• Soft packing

• Plywood

• Plastic wedges

5 - Moisture barrier

• On concrete and where there is a risk of moisture penetration, a moisture barrier, e.g. 0.20 mm PE membrane or 1000 g polythene is installed.

6 - Expansion gap at the wall

• 1.5 mm per m width on each side and 1 mm per m length at each end. All gaps should be a min. size of 12 mm (UK: min. 15 mm). Is also required at fixed points, e.g. columns.

Fig. 3

CONSUMPTION OF MATERIALS

Boards: approx. 2% wastage.

Nails: approx. 15 pcs. per m² (depending on batten centres and board width)

Battens: e.g. 39 x 40 mm:

c/c 600 mm: approx. 2 lin. m per m²

c/c 500 mm: approx. 2.4 lin. m per m²

Packings:

c/c 600 mm: approx. 4 pcs. per m²

c/c 500 mm: approx. 4.5 pcs. per m²

Moisture barrier: 25% extra for overlap + wastage