PRODUCT INFORMATION

Solid Hardwood Flooring | Product Information

B 6.0

B 6.0

PRODUCT DESCRIPTION

Junckers solid Boulevard planks are factory finished and ready to install in accordance to Junckers Laying Instructions.

The planks are made as one board and provided with a bevelled edge of approx. 0.5 mm.

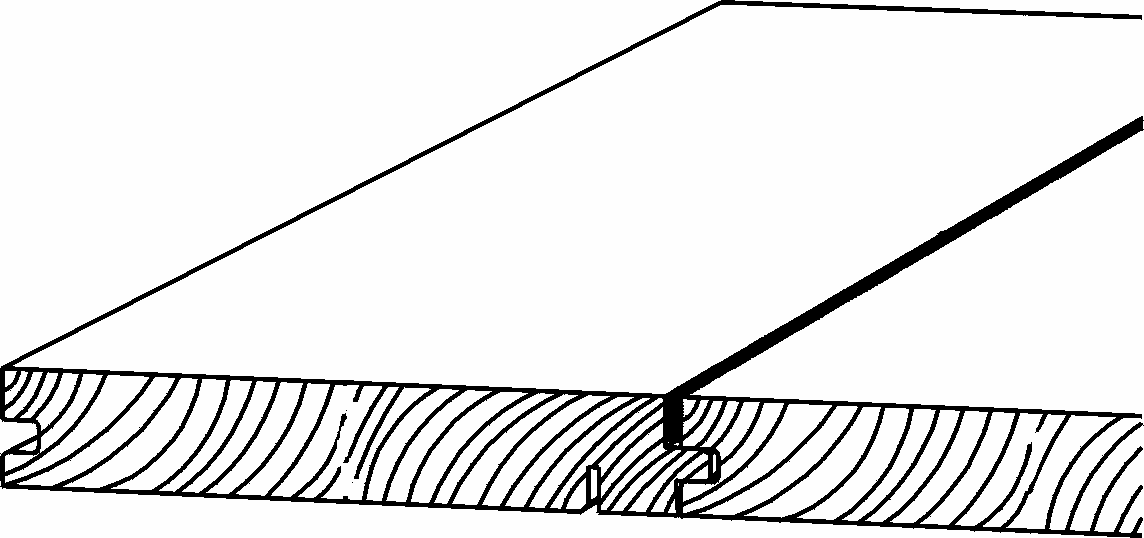

Each board is tongued and grooved on all four sides.

Fig. 2

Wood Species/Product name: Oak Boulevard - Black Oak Boulevard

Grade: Harmony

Surface: Ultra matt - Silk matt - Oiled - Untreated - Textured - Textured & coloured*

Wood Species/Product name: Nordic Oak Boulevard - Oak Pearl Boulevard

Grade: Harmony

Surface: Pigmented and Ultra matt Lacquered

Wood Species/Product name: Nordic Oak Boulevard

Grade: Harmony

Surface: Textured & coloured*

All products are available as Shipsdecking, see Fig. 2.

* According to standard product range

TECHNICAL PROPERTIES

Resistance to Indentation

All Oak products: Approx. 3.4 Hardness Brinell

Slip Resistance, (preliminary): Factory lacquered and oiled: Approx. 0.4 (DIN 18032/2)

Fire Classification, (DIN EN 13501-1): Cfl – S1

Thermal Conduction, (Transmission coefficient): Approx. 0.17 W/mK

Heat Resistance: Approx. 0.12 m² K/W

FACTORY SURFACE TREATMENT

Lacquered

Oak:

Priming: Several coats of UV-light curing primer.

Top finish: Two-component polyurethane lacquer, silk- or ultra matt.

Total film thickness: Min. 40 µ.

Nordic Oak:

Priming: Whitetone lacquer system.

Intermediate treatment: Several coats of UV-light curing lacquer.

Top finish: Two-component polyurethane lacquer, ultra matt. Total film thickness: Min. 40 µ.

Oak Pearl:

Priming: Water based transparent stain.

Intermediate treatment: Several coats of UV-light curing lacquer. Top finish: Two-component polyurethane lacquer, ultra matt. Total film thickness: Min. 40 µ.

Black Oak:

Pre-treatment: NH3-treatment to achieve the dark colour. Intermediate treatment: Several coats of UV-light curing lacquer. Top finish: Two-component polyurethane lacquer, ultra matt. Total film thickness: Min. 40 µ.

Oiled

Priming: Surface saturation using oxidative drying urethane oil.

Top finish: Oxidative drying urethane oil.

Total oil consumption: Addition to a full surface saturation.

Untreated

Final sanding to grit 150.

PACKING AND WEIGHT

Wrapped in polythene. 4 boards / layers of boards in each bundle. 1 layer can include mixed length, using standard board lengths, see Fig. 1. Orders can include mixed lengths of packs.

m² per pack according to package-length [mm]:

1500 / 1.11

1800 / 1.33

2100 / 1.55

2400 / 1.78

2700* / 2.00

3000* / 2.22

* Not Black Oak

Weight, kgs/m²:

All Oak products: 14.7

Fig. 1

PRODUCT DATA / TOLERANCES

Nominal Board Dimensions Thickness: 20.5 mm (±0.2 mm) Width: 185.0 mm (±0.2 mm) Length: 3000* / 2700* / 2400 / 2100 / 1800 / 1500 / 1200* / 900* / 600* mm (±1.0 mm).

* Not Black Oak

Drying Method

Boards are kiln dried.

Moisture Content

Boards are supplied with an average moisture content of: Oak: 8% (±2%).

Black Oak: 9% (±2%).

Precision Engineering

Landing Deviation: 0.2 mm (0.3 mm in localised areas).

Board ends are right angled at ±0.3mm.