SPECIFIERS INFORMATION FOR JUNCKERS GLUE DOWN SYSTEM

Solid Hardwood Flooring | Glue Down System Information

C 1.3.1

C 1.3.1

Fig. 1

C 1.0 General Information

C 1.3 Glue Down System

Information

C 1.3.1 Specifier's Information

C 1.3.2 Laying Instructions

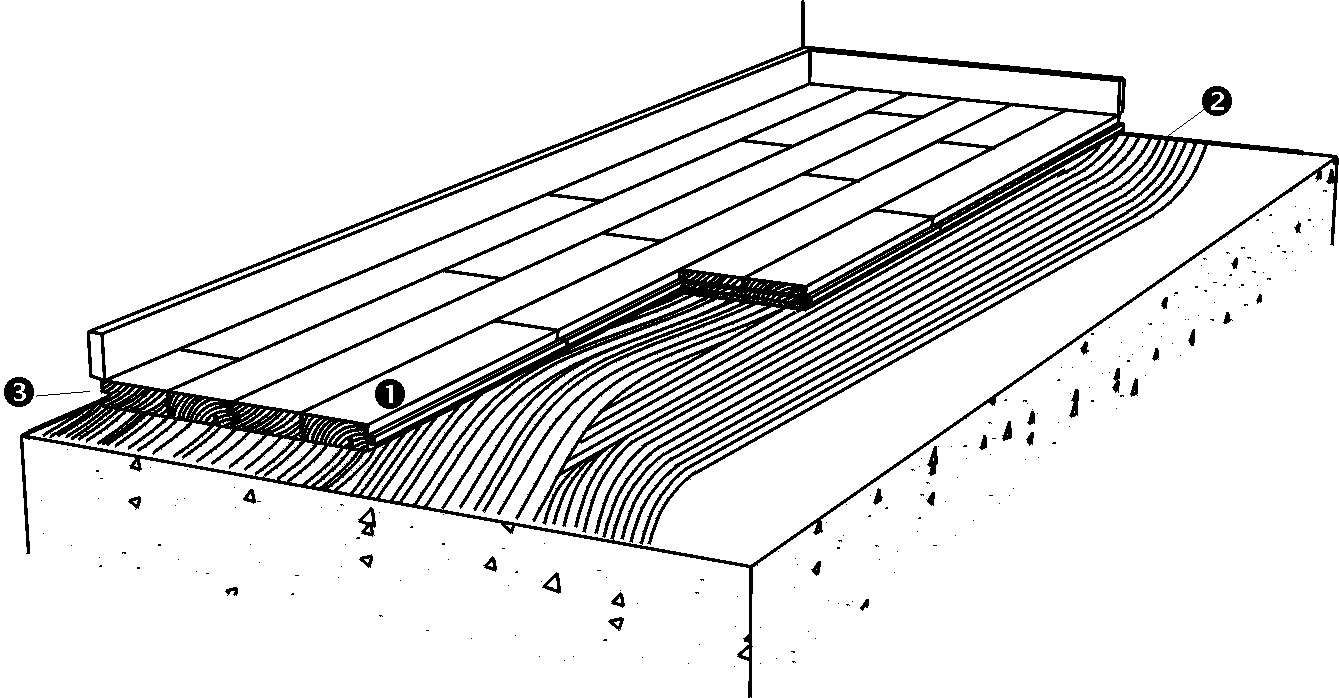

GENERAL DESCRIPTION OF FLOOR SYSTEM

This floor system consists of Junckers solid floors, see Fig. 2, glued to a dry loadbearing subfloor of concrete, lightweight concrete, screed or wooden material. The system is suitable for laying in both residential and commercial buildings, and can be laid in combination with underfloor heating systems, see E 4.3. Construction height from approx. 16 mm. Please note that full information on a floor system comprises the data in C 1.0, C 1.3, C 1.3.1 and C 1.3.2, see Fig.1.

SYSTEM SPECIFICATIONS

The glue down system is installed as a fully glued floor on a dry, loadbearing subfloor of concrete, lightweight concrete, screed or wooden material.

The subfloor must be flat, with a maximum deviation of 2 mm under a 1.5 metre straight edge (UK: 3 mm under a 2 m straight edge).

The surface must be smooth. Any minor irregularities must be corrected.

BOARDS

Boards are laid in a continuous, irregular pattern with header joints distributed randomly across the entire floor. To avoid waste, the off cut from the last completed row is used to start one of the following rows

EXPANSION JOINTS

To minimize the movements in the floor caused by fluctuations in the climatic conditions in the building, it will, for large commercial floors, be necessary to build in expansion joints. However existing expansion joints in the subfloor will decide the actual dividing of the flooring. Contact Junckers Technical Service for advice.

GLUE AND APPLICATION

For the gluing of the floorboards Junckers Parquet Glue is to be used. The glue is applied using Junckers spatula. Use approx. 0.5-0.6 litre per m², depending on the absorption capacity, structure and flatness of the subfloor, see C 1.3.

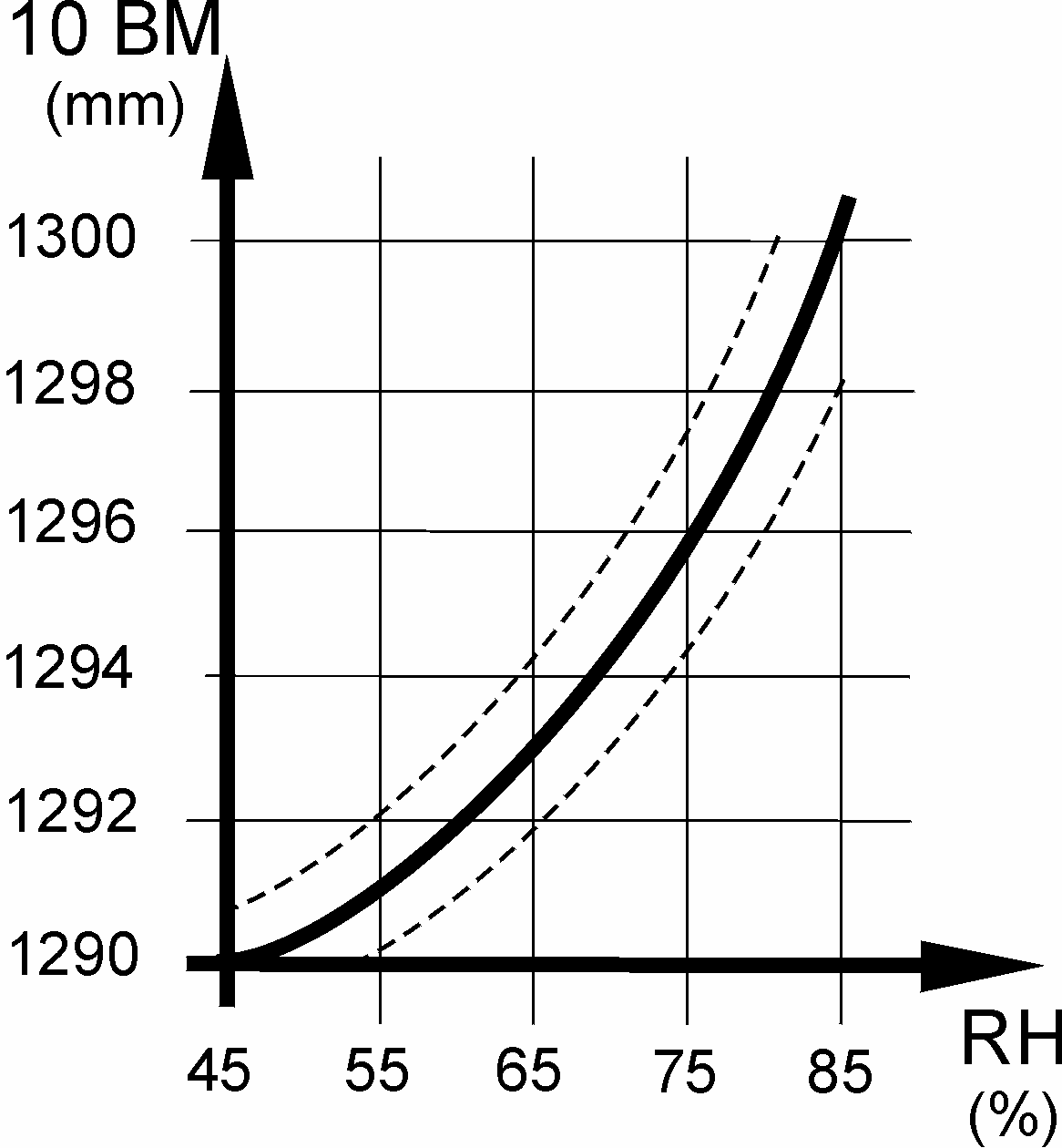

10-BOARD MEASUREMENT

In order to minimize stress, distortion or gaps in the floor due to fluctuations in the climatic conditions within the building, boards must be laid according to a 10-board rule. This indicates the measurement across 10 boards when laid and should be checked continuously during installation and afterwards, see Fig. 4.

To keep the fixed 10-board measurement (10 BM), it is recommended to use spacers when installing the floor. Table 1 shows the choice of spacers and 10 BM for boards with width 129, 140 and 185 mm based on the subfloor structure and the expected maximum relative humidity in the building, see Fig. 5.

| Max. RH | Subfloor structure | Spacers | 10 BM (mm) | ||

| 129 mm | 140 mm | 185 mm | |||

| 65 % |

- Wood-based subfloor |

0.2 mm (red) |

1292 | 1402 | 1852 |

| - Concrete ground floor, etc. | 0.4 mm (green) |

1294 | 1404 | 1854 | |

| 75 % | - Wood-based subfloor - Concrete upper floor |

0.6 mm (yellow) | 1296 | 1406 | 1856 |

| - Concrete ground floor, etc. | 0.8 mm (purple) | 1298 | 1408 | 1858 | |

Use: Spacers are used at max. 900 mm between all board-rows up to 3 m back in the laying direction. This gives a consumption of approx. 25 spacers per metre of floor, calculated in the lengthwise direction of the boards. For shipsdecking a 10-board measurement of 1298, 1408 and 1858 mm is always used so that on assembly the Shipsdecking strip is always slightly compressed. In case of doubt please contact Junckers technical service.

Fig. 4

Fig. 5

LOADBEARING STRENGTH

The loadbearing strength of the floor system depends on the type of load. Table 2 presents loadbearing strength in accordance with the load classes.

For further definition of load classes and types, see C 1.0

| Loading types | ||

|

Loading category |

Area- and Point load | Wheel load |

| A+B Residential + Office |

Approved (all products) | Approved (all products) |

| C1 + C2 + C3 + D1: Public buildings and shoppings areas |

Approved (all products) | Approved (all products) |

CONSUMPTION OF MATERIALS

Boards: approx. 2% wastage

Junckers Parquet Glue: approx. 0.6 litres per m² (incl. waste)

Junckers Liquid Moisture Barrier: 225 g per m² as moisture barrier and 125 g per m² as primer.

Junckers Spatula: 1 pcs.

Fig. 2

COMPONENTS

1 - Boards

• Junckers 14 and 22 mm 2-strip Boards, incl. shipsdecking

• Junckers 15 and 20.5 mm Planks, incl. shipsdecking.

Wood species, dimensions, grades and finish:

22 x 129 mm Solid 2-strip: see B 2.0

14 x 129 mm Solid 2-strip: see B 3.0

20.5 x 140 mm Planks: see B 5.0

20.5 x 185 mm Planks: see B 6.0

15 x 129 mm Planks: see B 7.0

2 - Glue and moisture barrier

• Junckers Parquet Glue, see H 6.1

• Junckers Liquid Moisture Barrier (if required), see H 6.5

3 - Expansion gap at the wall

• 1.5 mm per m of floor width on each side and 1 mm per m length at each end. All gaps should be a min. size of 12 mm (UK: min. 15 mm). Is also required at fixed points, e.g. columns.

Fig. 3