LAYING INSTRUCTION

BLUBAT SPORTS FLOOR SYSTEM

D 6.2.1

D 6.2.1

Fig. 1

D 1.0 General information

D 1.2 Batten System Information

D 6.2 Specifier's Information

D 6.2.1 Laying Instructions

BEFORE LAYING THE FLOOR

The building must be weather tight. The heating system must be installed and tested, and during the heating season there should be a constant heat supply. Cast concrete elements, including casting of sockets for fixtures and fittings, screeding and other wet trades which can contribute moisture to the building, e.g. priming of paintwork, must also be completed.

The relative humidity in the building must be between 35 - 65% RH (UK) and the temperature approx. 16-20°C. The residual moisture contained in the concrete or screed must not exceed 90% RH. (UK: 75% acc. To BS 8201). In wooden based sub floors the moisture content should not exceed 12%.

Solid boards should always be laid immediately after arrival at the building. The packing on the bundles must not be removed until just prior to laying the floor, i.e. no acclimatising of the boards on site must take place.

NB: Read these instructions carefully before laying begins. In case of doubt please contact your Junckers distributor before installing the floor.

Fig. 2

1. SUB-FLOOR CONDITION

The sub-floor must be levelled to a tolerance of no more than 2 mm gap showing under a 1.5 m straight edge (UK: No more than a 3 mm gap showing under a 2 m straight edge).

The surface must be smooth with no roughness. Local irregularities, e.g. above day joints, must be levelled.

Fig. 3

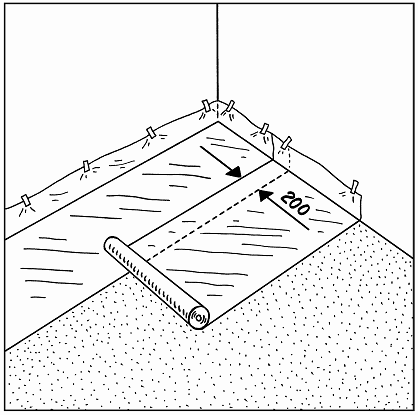

2. MOISTURE BARRIER

A moisture barrier of min. 0.20 mm PE membrane is laid, e.g. Junckers Moisture Barrier. The moisture barrier is laid with an overlap of 200 mm at all joints, continuing up walls, etc. The polythene has to be taped at all lap joints.

Fig. 4

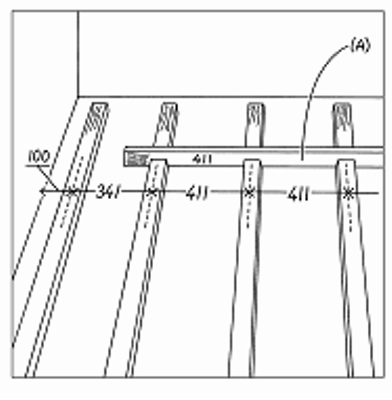

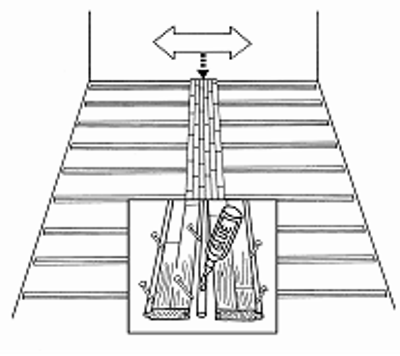

3. LAYING OF SUBSTRUCTURE - BATTEN CENTRES 411 MM

The battens are laid parallel to the shortest side of the room to ensure that the boards are laid parallel to the longest side of the room. The first and last rows of battens are laid with a distance of 100 mm from the wall to the centre of the batten. The second batten row is centred at 341 mm to the first batten row. All other batten rows are centred at 411.1 mm by using the Spacing Battens (A).

Batten end joints should not be in line, but must be staggered min. 600 mm from the neighbouring row. The entire substructure must be placed with an expansion gap of minimum 30 mm from all walls, net posts, pipes, etc.

NB: If the floor is used as a squash court permanent spacing blocks at 500 mm centres are attached between the first batten row and the end wall where the play is performed.

Fig. 5

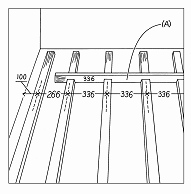

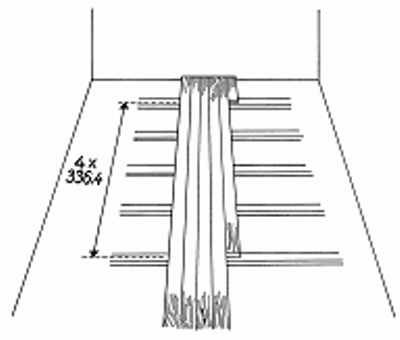

4. LAYING OF SUBSTRUCTURE - BATTEN CENTRES 336 MM

Except for the batten distance, the battens are laid according to the instructions in part 3 (above).

If the floor is used for basketball or retractable seatings are to be installed in the sports hall, battens with c/c 336 mm shall always be used.

The first and last rows of battens are laid with a distance of 100 mm from the wall to the centre of the batten. The second batten row is centred at 266 mm to the first batten row. All other batten rows are centred at 336.4 mm by using the Spacing Battens (A).

Fig. 6

5. LAYING OF SUBSTRUCTURE

Place extra loose battens at net posts, pipes, etc. Loose battens must be elastic.

Distance to all walls, net posts, pipes, etc. see section 3.

Fig. 7

6. LAYING OF BOARDS

If the floor is more than 12 m wide the laying must begin in the middle of the sports hall. The two centre boards are joined with a loose tongue which is glued to both boards the full length of the boards.

The boards are secret nailed, see section 10.

Fig. 8

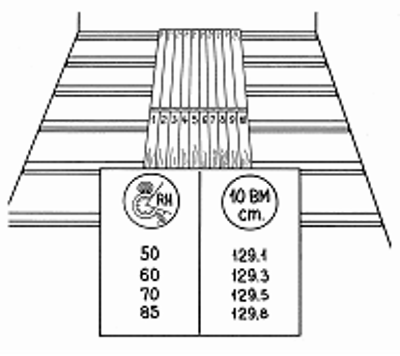

7. 10-BOARD RULE

To avoid as far as possible stress or moisture formation in the floor, due to fluctuations in the climatic conditions in the building, the boards must be laid according to the 10-board rule which indicates the width of 10 boards when laid. Compliance must be checked continuously.

The 10-board rule is chosen on the basis of the maximum expected relative humidity of the building over the year. An expected relative humidity for example of max. 65 % RH will normally require a 10-board measurement of approx. 1294 mm, see also D 1.2.

The measurement is achieved by inserting temporary spacers between the boards during the installation process.

In case of doubt please contact Junckers Technical Services

Fig. 9

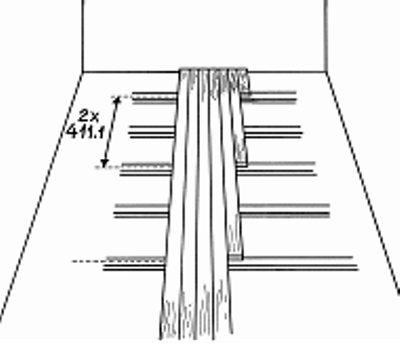

8. BOARD PATTERN - BATTEN CENTRES 411 MM

All board header joints must be fully supported and, depending on the batten centres (336 or 411 mm) all boards must be laid in the pattern shown in the drawing.

If the batten centres is 411.1 mm, the distance between board header joints in two consecutive rows must be 2 x 411.1 mm = 822.2 mm, as shown in the drawing.

Fig. 10

9. BOARD PATTERN - BATTEN CENTRES 336 MM

If the batten centres is 336.4 mm, the distance between board header joints in two consecutive rows must be 4 x 336.4 mm = 1345.6 mm, as shown in the drawing.

Fig. 11

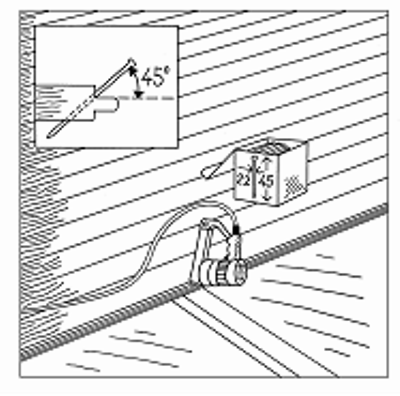

10. NAILING

Use Junckers machine J-Nails, 2.2 x 45 mm.

The boards are secret nailed at an angle of 45°. Do not nail closer than 50 mm to stave joints and never in the board end joints.

To avoid creaking, the boards are pressed down on the battens while they are nailed.

The distance between the floorboards and walls/vertical fixed installations is calculated as 1.5 mm per running metre of floor width on each side, and at end walls 1 mm per running metre of floor length, with an overall distance of minimum 30 mm.

NB: The first and last rows of boards installed must be face nailed or screwed and then covered with matching filler.

Fig. 12

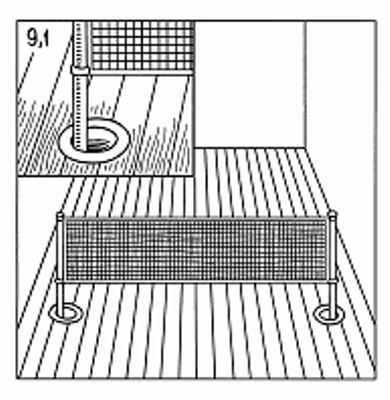

11. BUSHINGS

On mounting of bushings in the surface of the floor the internal diameter of the bushing must exceed that of the pipe, i.e. the external diameter of the net pole, by at least 40mm. At the outermost zones of the floor all bushings are mounted eccentrically towards the middle of the floor in relation to the sockets in the concrete.

NB: Floor rosettes must be mounted to allow both vertical and horizontal movement of the floor to take place unimpeded.

Fig. 13

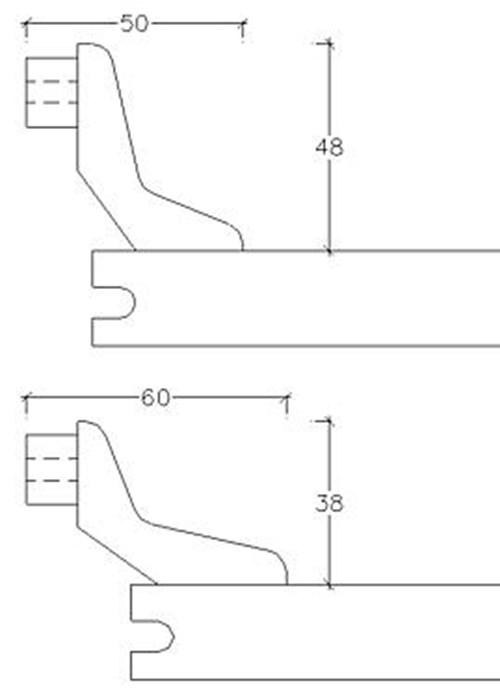

12. SKIRTING

Junckers Combi Sports Skirting is installed.

The skirting can also be mounted by another method, provided that it ensures the free movement of the floor and includes ventilation space.