SPECIFIER'S INFORMATION

DUOBAT 120+ SPORTS FLOOR SYSTEM

D 7.2

D 7.2

Fig. 1

D 1.0 General information

D 1.2 Batten System Information

D 7.2 Specifier's Information

D 7.2.1 Laying Instruction

GENERAL DESCRIPTION OF FLOOR SYSTEM

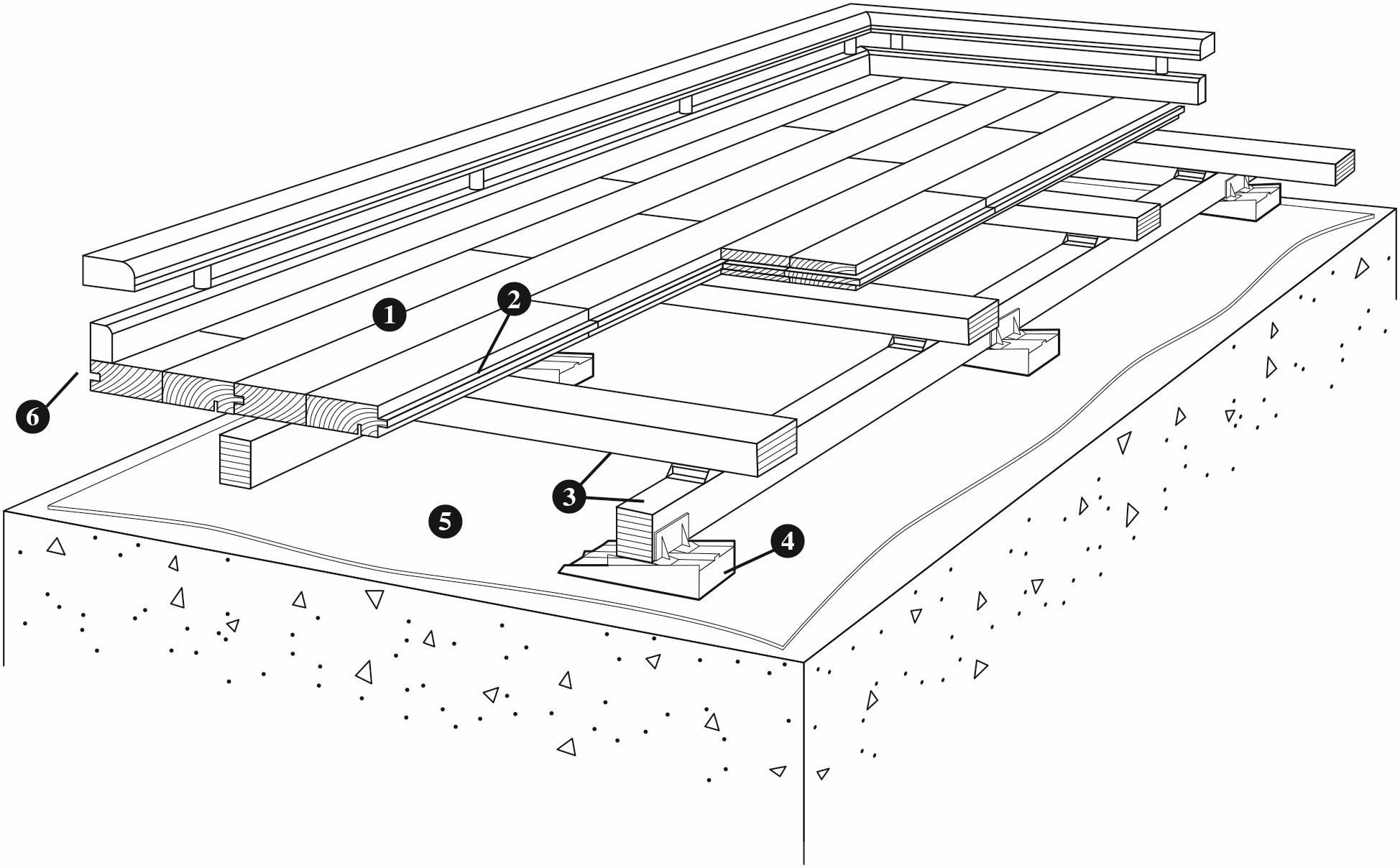

Junckers DuoBAT 120+ Sports Floor System is based on 22 mm solid hardwood floor boards nailed to a resilient subfloor of two layers of crosswise-laid prefabricated battens. The floor system is an area elastic type of sports floor with a structural design providing an extremely homogeneous floor surface with very high shock absorbency and elasticity particular suitable in multi-purpose sports halls with fast ball games and gymnastics. The floor system is normally used on an unlevelled subfloor and comes with clip-on wedges (DuoWedges) for easy levelling of the floor system.

Construction height using the DuoWedge: From 120-142mm.

Packing blocks that can be clipped to the underside of the DuoWedges are available in a variety of thicknesses (20, 30, 40, 50mm) to easily increase the height of the floor system if required. Don´t use more than 2 packing blocks under each wedge.

The sports floor system fully conforms to EN 14904:A4.

Please note that full documentation of a floor system comprises the data in D 1.0, D 1.2, D 7.2 and D 7.2.1, see Fig. 1.

Fig. 3

SYSTEM SPECIFICATIONS

22 mm solid boards nailed to a substructure of veneered prefabricated battens. Manufactured as a double-batten structure of 25.5 x 60 mm upper battens and 39 x 40 mm lower battens with resilient J-Lock shock pad mounted between the battens where they cross. The resilient elements are pre-mounted on the upper battens and are clippedon to the lower battens during installation by the pre-mounted J-Lock element.

Packings (DuoWedges) of the substructure are clipped-on onto the lower battens where marked. To avoid deflection of the floor along the walls, special battens, called Gableand Face Wall Battens, are included in the system. As a help to get started with the correct staggering of the Lower Battens, special battens, called Start Battens, are included as well.

The system is levelled up on a firm subfloor using Junckers DuoWedges.

BOARDS

The boards are nailed to the battens according to a fixed 10-board rule, see D 1.2.

The boards are laid in a continuous pattern with well-defined distribution of board header joints from row to row of 4 x the batten centres, i.e. 1345.6 mm with c/c 336.4 mm. In that way that all board headerjoints are supported, see also D 7.2.1.

Fig. 4

POINTLOAD-BEARING STRENGTH

The DuoBAT 120+ Sports Floor System is tested and approved for below mentioned maximum point loads, in relation to load area:

Diameter, 25 mm: 4.5 kN ( 450 kg) 100x100 mm: 6.0 kN ( 600 kg)

LOAD-BEARING STRENGTH

The DuoBAT 120+ Sports Floor System is designed to ensure good technical properties in relation to the expected loads in connection with sports activities.

The load-bearing strength of the system depends mainly on the loading type and load area.

Table 1 shows use of the floor system in relation to the load classes in EN 1991-1-1.

See Fig. 4 for specifik point load bearing strength.

For further definition of load classes and types, see D 1.0 - Stiffness and loadbearing strength.

| Table 1 | Loading types | |

| Loading category | Area- and Point load | Wheel load |

| C4: Assembly halls for physical activity, e.g. gyms/theatres | Approved* | Approved** |

| C5: Assembly halls which can be crowded, e.g. sports halls incl. stands. | Approved | Approved** |

* Point load area min. 200 x 200 mm

** Wheel loads, see D 1.0 - Table 2

Fig. 2

COMPONENTS

1 - Boards

Junckers 22 mm 2-strip boards for sport.

Wood species: Beech, SylvaKet, Maple and Ash.

Grades: Champion, Premium and Club.

See also B 2.0

2 - Nails

2.2 x 45 mm Junckers J-Nails.

3 - Duobat 120+ batten system

Upper battens 25.5 x 60 mm, c/c 336.4 mm.

J-Lock shock pad elements: 12 mm resilient elements pre-mounted on upper batten, and J-Lock elements pre-mounted on lower batten.

Lower battens 39 x 40 mm, c/c 400 mm.

Start Battens 39 x 40, c/c 400 mm.

Gable battens 39 x 40 mm.

Face Wall battens 39 x 40 mm with 14 mm plywood feet.

4 - Packings

DuoWedges, 4.5 pcs. per m².

5 - Moisture barrier

Junckers Moisture Barrier, see also D 1.2.

6 - Expansion gap at the wall

1.5 mm per metre width on each side and 1 mm per metre length at each end, but both min. 30 mm. Is also required at fixed points, e.g. columns, see also D 1.2.

CONSUMPTION OF MATERIALS

Net consumption for 1000 m² (Length x width = 40 x 25 m) DuoBat 120+ batten system:

| Boards: | 1000 m² + 2% wastage |

| Lower Battens: | 2400 rnm + 2% wastage |

| Upper Battens | 2975 rnm + 2% wastage |

| Start Battens | 62 pcs |

| Gable Battens | 2 x width = 50 rnm |

| Face Wall Battens | 2 x length = 80 rnm |

| J-Nails | 25,000 pcs |

| Loose J-Lock shock pads | 100 pcs. (1 box) |

| Packings (DuoWedges) | approx. 4,500 pcs |

| Loose tongues | 67 pcs (5 bags) |

| Moisture Barrier | 1000 m² + 15% wastage |

| Header joint adhesive | 3 bottles (3 x 0.75 litre) |