SOLID HARDWOOD FLOORING

BATTEN SYSTEM INFORMATION

Underfloor heating

Commercial / Residential

E 4.2

E 4.2

UNDERFLOOR HEATING

E 4.0 General Information

E 4.2 Batten System Information

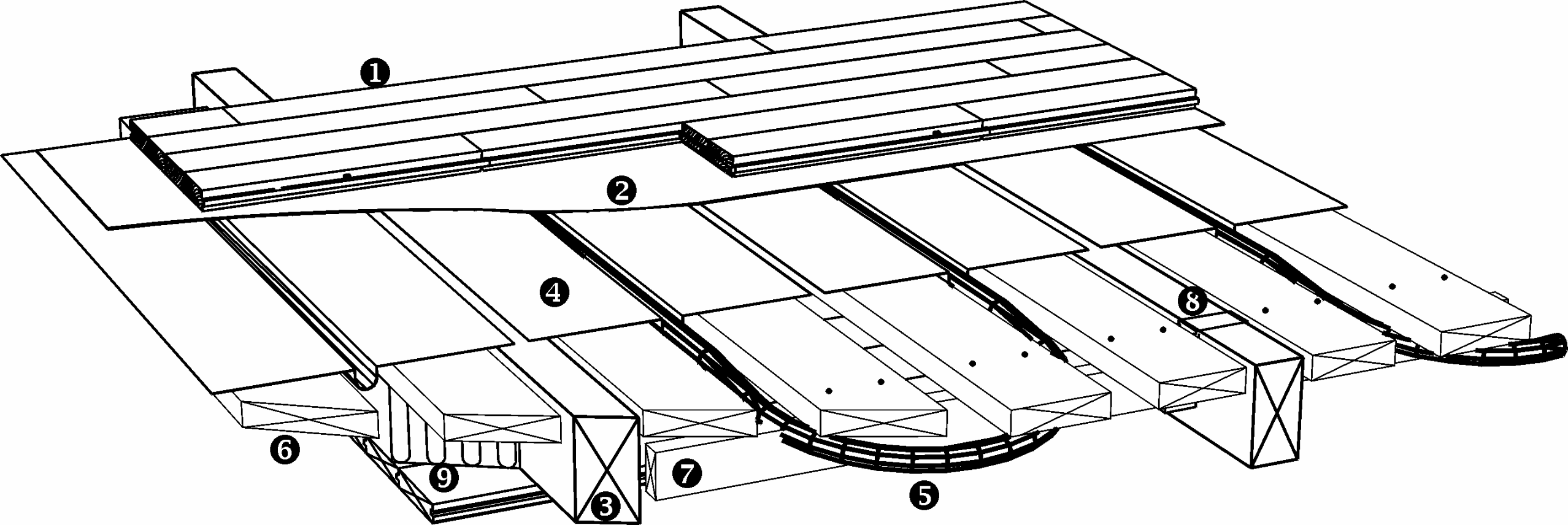

Fig. 1

INTRODUCTION

These instructions apply to all Junckers Solid hardwood boards nailed to battens, joists or a subfloor of bearers in which heating pipes are installed inheat-distribution plates. Please note that full documentation of a floor system nailed to a wooden substructurewith a built-in underfloor heating system comprises the data in E 4.0 and E 4.2, see Fig. 1.

Reference is also made to Junckers Batten Systems, see C 1.2.

GENERAL INFORMATION

Battens, joists and other wooden material included in substructures with underfloor heating systems should generally have lower moisture content than normally specified because the wood will dry out more – in ideal conditions max. 10%. Veneer-laminated battens and joists supplied with a moisture content of 8-10% are therefore particularly suitable.

Insulation up to the underside of the heat-distribution plates and heating pipes will reduce the heat loss.

COMPONENTS

1 - Boards

• Junckers 22 mm 2-strip boards, incl. ships decking

• Junckers 20.5 mm Planks, incl. shipsdecking.

Nailed to bearers with: Junckers J-nails (machine nails) or 2.6 x 65 mm T-nails (machine nails) in every third bearer or 450 mm c/c.

2 - Intermediate layer

• floor cardboard, 500 g/m²

3 - Heat-distribution plates

4 - Floor heating pipes

5 - Bearers

• 25 x 100 mm, planed on one side, c/c distance: 150 mm

6 - Insulation

7 - Battens / Joists

• Maximum c/c distances:

Residential: 600 mm

Commercial: 500 mm 8 - Packings

9 - Moisture barrier

• 0.20 mm PE membrane

Fig. 2

NAILING TO BEARERS ACROSS BATTEN & JOIST FRAMEWORK

2-strip boards or planks can be nailed to a self-supporting underlay of bearers mounted on battens/joists. Heat-distribution plates, in which heating pipes are installed, are fixed on to the bearers.

The load bearing strength of the bearers must be suitable for the use of the floor. The bearers are supported by battens/joists. For residential and office/light industrial interiors a distance of 600 mm is suitable, while for industrial, i.e. public buildings/shops battens/joist should be at maximum 500 mm. The bearers must be planed on one side so that the thickness does not vary more than ± 0.5 mm, and must also have a residual thickness which leaves enough room for the heat-distribution plates. The thickness is usually minimum 23 mm.

Please note that in this example the floorboards lie parallel to the bearing battens/joists.

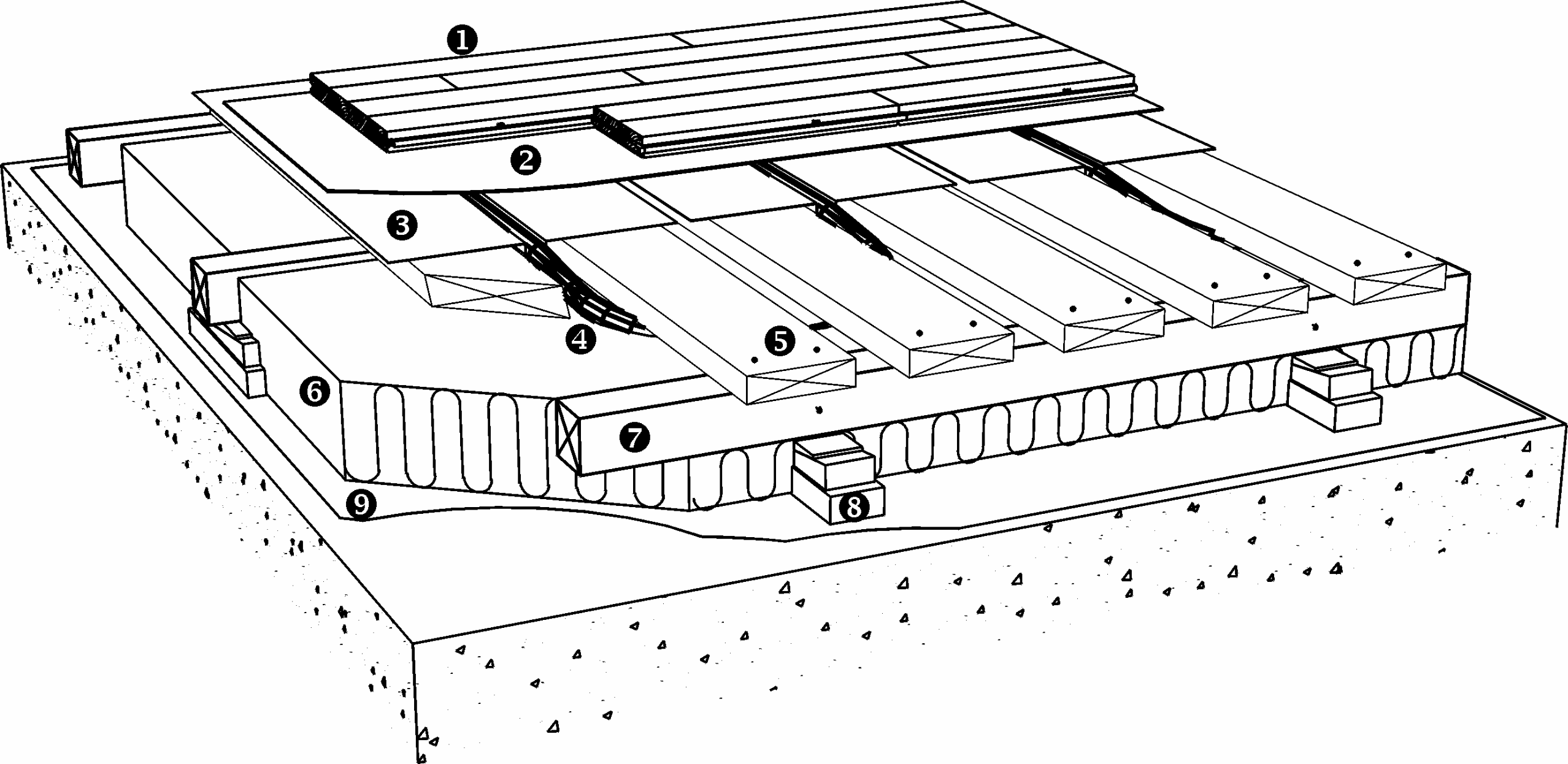

Fig. 3

COMPONENTS

1 - Boards

• Junckers 22 mm 2-strip boards, incl. ships decking

• Junckers 20.5 mm Planks, incl. shipsdecking.

Nailed to battens/joists with: Junckers J-nails (machine nails) or 2.6 x 65 mm T-nails (machine nails)

2 - Intermediate layer

• floor cardboard, 500 g/m²

3 - Battens / Joists

• Maximum c/c distance: 600 mm

4 - Heat-distribution plates

5 - Floor Heating pipes

6 - Bearers

• 25 x 100 mm, c/c distance: 150 mm

7 - Noggins

8 - Fittings for noggins

9 - Ceiling + insulation

Fig. 4

NAILING TO BATTEN/JOIST FRAMES WITH UNDERFLOOR HEATING

Both 22 mm solid 2-strip boards and 20.5 mm solid planks can be nailed to battens/joists which have an underfloor heating system built in between.

The underfloor heating system comprises heat-distribution plates with heating pipes laid on a wooden underlay of bearers boards, supported by noggins attached to battens/joists.

To avoid creaking, floor cardboard, 500 g/m², is placed as an intermediate layer on the heat-distribution plates before the floorboards are installed.

To achieve the best possible temperature distribution the heat-distribution plates must be in close contact with the floor surface and the intermediate layer. This is done by mounting the upper side of the bearer’s level with the upper side of battens/joists.

The maximum 600 mm spacing of battens or joists makes this floor structure suitable for use in residential and office/light industrial interiors

Fig. 5