SPECIFIER INFORMATION

JUNCKERS PORTABLE A3 SPORTS FLOOR SYSTEM | LAYING INSTRUCTION

D 3.1

Fig. 1

D 1.0 General information

D 1.1 Clip Sports Information

D 3.1 Specifier's Information

D 3.1.1 Laying Instruction

GENERAL DESCRIPTION OF FLOOR SYSTEM

Junckers Portable Flooring System is based on 22 mm solid boards, prefabricated into panels/elements and laid floating on resilient foam underlay. The floor system is an area elastic type of sports floor with medium shock absorbency and elasticity suitable for fitness and aerobics as well as a temporarily sports floor, e.g. with special line markings for a given sports game.

The construction height is 27 mm or 32 mm, depending on the thickness of the foam underlay.

The floor system when 10 mm foam is used will conform to EN 14904:A3.

Please note that full documentation of a floor system comprises the data in D 1.0, D 1.1, 3.1 and D 3.1.1, see Fig. 1.

Fig. 3

SYSTEM SPECIFICATIONS

The Portable A3 Sports Floor System is installed as a floating floor on a dry, load-bearing floor of concrete, lightweight concrete or wooden materials, e.g. an existing sports floor.

The subfloor must be flat with a maximum deviation of 2 mm under a 1.5 m straight edge (UK: 3 mm under a 2 m straight edge). The surface must be smooth. Any minor irregularities must be corrected. The choice of intermediate layer depends on the structure of the subfloor and the moisture conditions.

FLOOR ELEMENTS

The elements are laid in an interlocking pattern so that all joints are staggered 900 mm from row to row. The elements are locked together with pre mounted assembling fittings. Lengthwise the elements have a tongue and groove connection and at ends the elements are joined using loose tongues.

NB: Centre Row elements are available on request with this system. Centre Row elements comes with assembly frames on each side of the elements, and are laid out in the middle/centre of the floor as a starting row

SPACING TO WALLS AND FIXED INSTALLATIONS

2 mm per metre of floor width on each side, min. 30 mm. Is also required at fixed points, e.g. columns.

RESILIENT MAT

The choice of resilient mat depends on the properties of the subfloor. If the subfloor is fully or partly inelastic Junckers 10 mm Sports Foam is used, while for elastic subfloors, e.g. existing sports floors with certain resilient properties, Junckers 5 mm Sports Foam.

ACCESSORIES

Transport trolley: Designed to load 40 pcs. of 1/1 elements

Perimeter trims: Metal ramp as finish of the floor

Removal hook: For removal of loose tongues when dismantling the elements

Loose tongues: Supplied in plastic

See also H 5.0

MOISTURE BARRIER

On ground floors and where there is a risk of moisture penetration a moisture barrier of 0.20 mm PE membrane, e.g. Junckers Moisture Barrier, is laid directly on the concrete.

Fig. 4

POINTLOAD-BEARING STRENGTH

The Portable A3 Sports Floor System is tested and approved for below mentioned maximum point loads, in relation to load area:

Diameter, 25 mm: 3.5 kN ( 350 kg) 100x100 mm: 4.0 kN ( 400 kg)

LOAD-BEARING STRENGTH

The load-bearing strength of the clip system depends on the load, load area and subfloor type. The floor's total transverse expansion can also play a role, depending on the climate conditions in the hall. Table 1 shows use of the floor system in relation to the load classes in EN 1991-1-1. See Fig. 4 for specific point load bearing strength.

For further definition of load classes and types, see D 1.0 - Stiffness and loadbearing strength.

| Loading types | ||

|

Loading category |

Area-and Point load | Wheel load |

| C4: Assembly halls for physical activity, e.g. gyms/theatres | Approved* | Approved** |

| C5: Assembly halls which can be crowded, e.g. sports halls incl. stands. | Approved | Approved** |

* Point load area min. 200 x 200 mm

** Wheel loads, see D 1.0 - Table 2

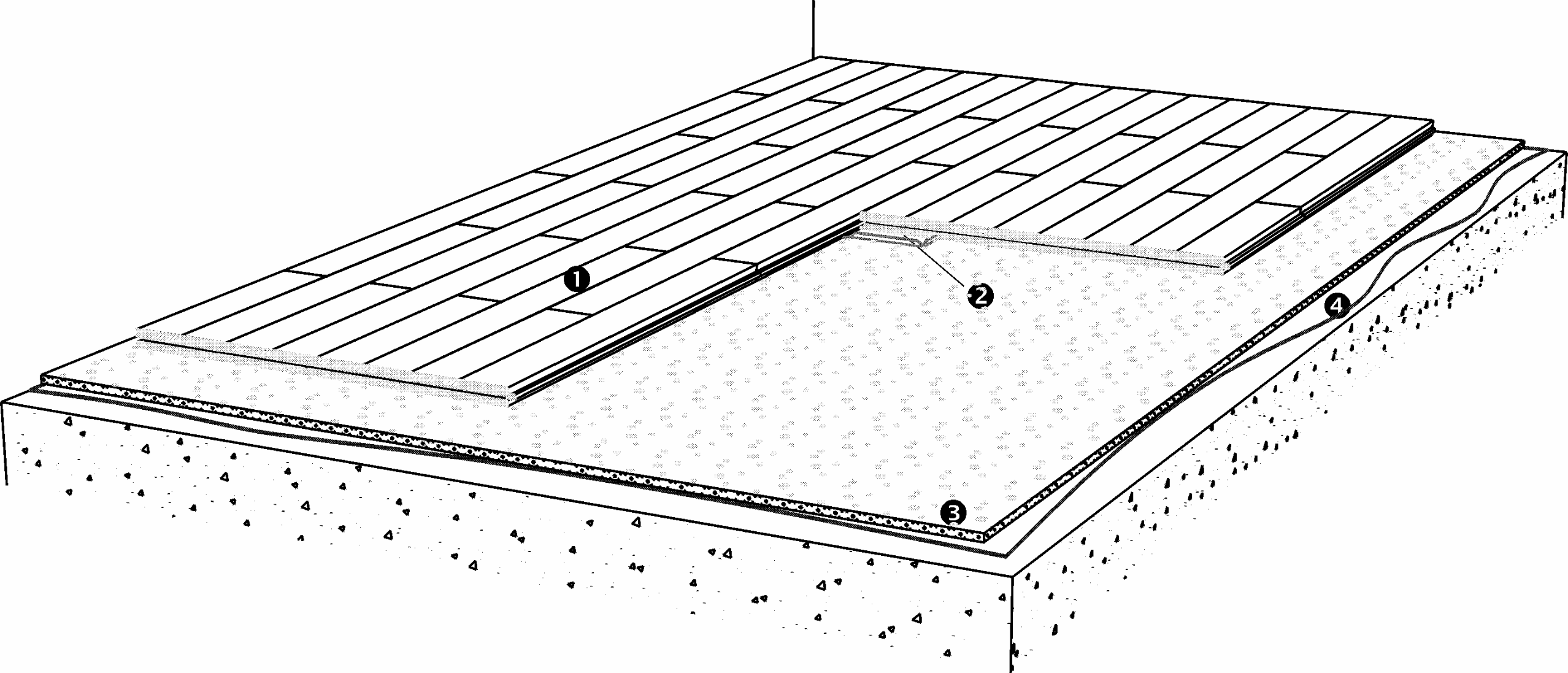

Fig. 2

COMPONENTS

1 - Floor Elements

• Junckers 22 mm solid boards for sport.

Wood species and grades: Beech Premium and Maple Champion, lacquered.

Element width x length:

1/1 element: 513 x 1800mm

1/2 element: 513 x 900 mm

2 - Fittings

• Pre mounted assembling fittings.

3 - Skirting (accessories)

• Perimeter ramp made as corner profiles and profiles in 2 meter lengths in metal.

4 - Intermediate layer

• 5 mm Junckers Sports Foam.

• 10 mm Junckers Sports Foam.

5 - Moisture barrier on concrete

• Min. 0.20 mm PE membrane, e.g. Junckers Moisture Barrier.

CONSUMPTION OF MATERIALS

Net consumption for a basketball court according to the official FIBA rules 19 x 32 metres (incl. a 2 metres safety zone around the court):

1/1 Elements: 665

1/2 Elements: 38

Loose tongues: 717 pcs.

Resilient mat: 632 m²

Optional moisture barrier: 700 m² incl. overlaps

NB: The actual area of floor will due to the floor elements size in most cases be slightly bigger than the calculations figures.