LAYING INSTRUCTION

Junckers A3 Portable Sport Floors

D 3.1.1

D 3.1.1

Junckers Portable A3 Floor System

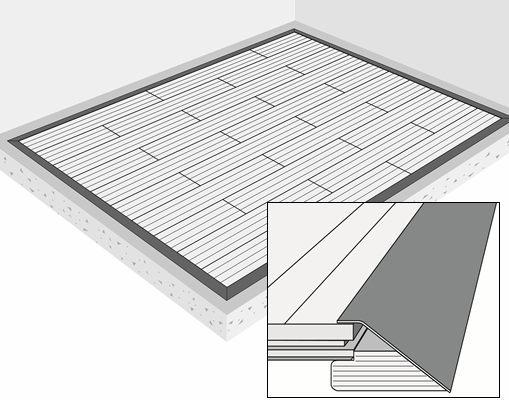

D 1.0 General information

D 1.1 Clip System Information

D 3.1 Specifier's Information

D 3.1.1 Laying Instructions

BEFORE LAYING THE FLOOR

The building must be weather tight. The heating system must be installed and tested, and during the heating season there should be a constant heat supply. Cast concrete elements, including casting of sockets for fixtures and fittings, screeding and other wet trades which can contribute moisture to the building, e.g. priming of paintwork, must also be completed.

The relative humidity in the building must be between 35 - 65% RH (UK) and the temperature approx. 16-20°C. The residual moisture contained in the concrete or screed must not exceed 90% RH. (UK: 75% acc. To BS 8201). In wooden based sub floors the moisture content should not exceed 12%.

The elements must be stored under the same climatic conditions as when the floor is used.

NB: Read these instructions carefully before laying begins. In case of doubt please contact your Junckers distributor before installing the floor.

1. SUB-FLOOR CONDITION

The sub-floor must be levelled to a tolerance of no more than 2 mm gap showing under a 1.5 m straight edge (UK: No more than a 3 mm gap showing under a 2 m straight edge).

The surface must be smooth with no roughness. Local irregularities, e.g. above day joints, must be levelled.

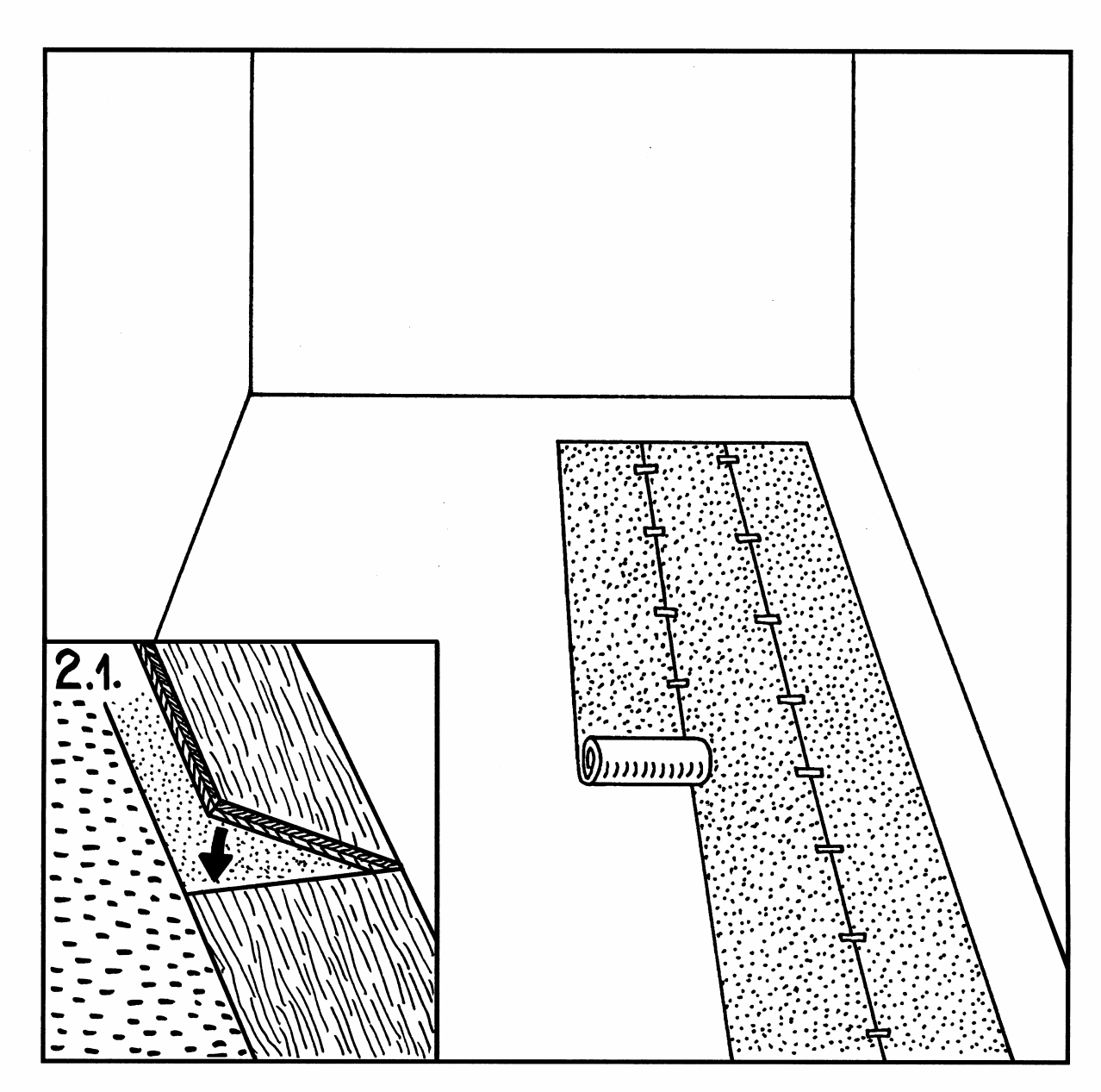

2. MOISTURE BARRIER AND SPORTSFOAM

In general protection against moisture both from within the building and from the ground is required when the floor is installed. Use e.g. Junckers Moisture Barrier or similar.

Junckers Sportsfoam mat is laid parallel to the laying direction of the elements with joints fully closed and taped in place.

If part or all of the subfloor is inelastic a 10 mm foam mat is used, while for elastic subfloors, e.g. existing sports floors with certain sports-related properties, a 5 mm foam mat is used.

NB: For floors subject to heavy loads, e.g. from portable basketball stands, etc., the resilient foam along the perimeter of the floor can be replaced by plywood, to prevent undesirable deformation of and thereby damage to the elements, see Fig. 2.1.

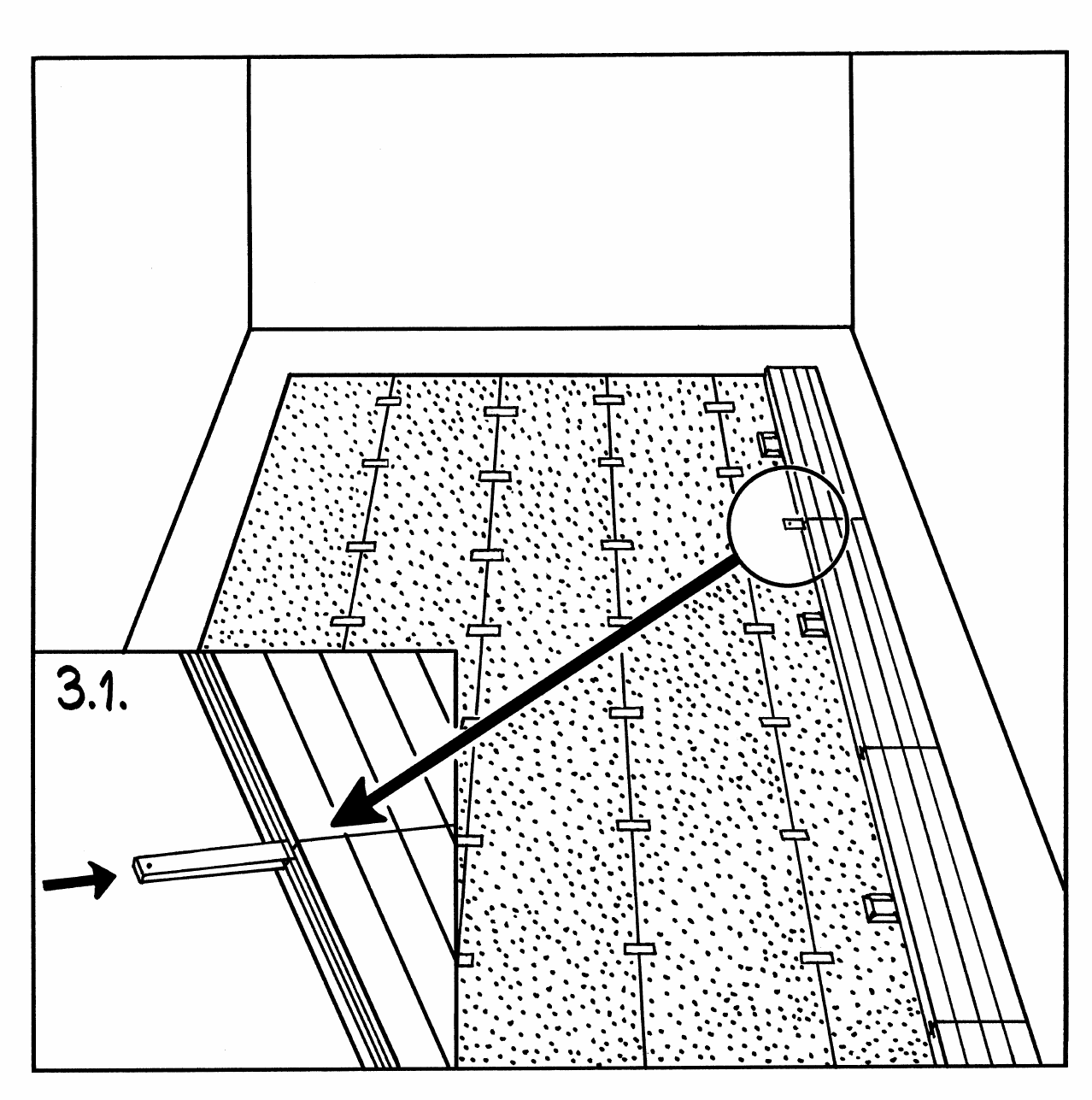

3. LAYING OF PORTABLE ELEMENTS

The first row of elements is laid in a straight line with the assembly frame pointing in the laying direction. The elements are joined at ends using loose joining tongues, see Fig. 3.1.

First time the floor is laid all the elements should be numbered on the back or on the assembly frame, to ensure that they are correctly placed each time the floor is laid, so that line markings, etc. are aligned.

NB: Centre Row elements are available on request with this system. Centre Row elements comes with assembly frames on each side of the elements, and are laid out in the middle/centre of the floor as a starting row.

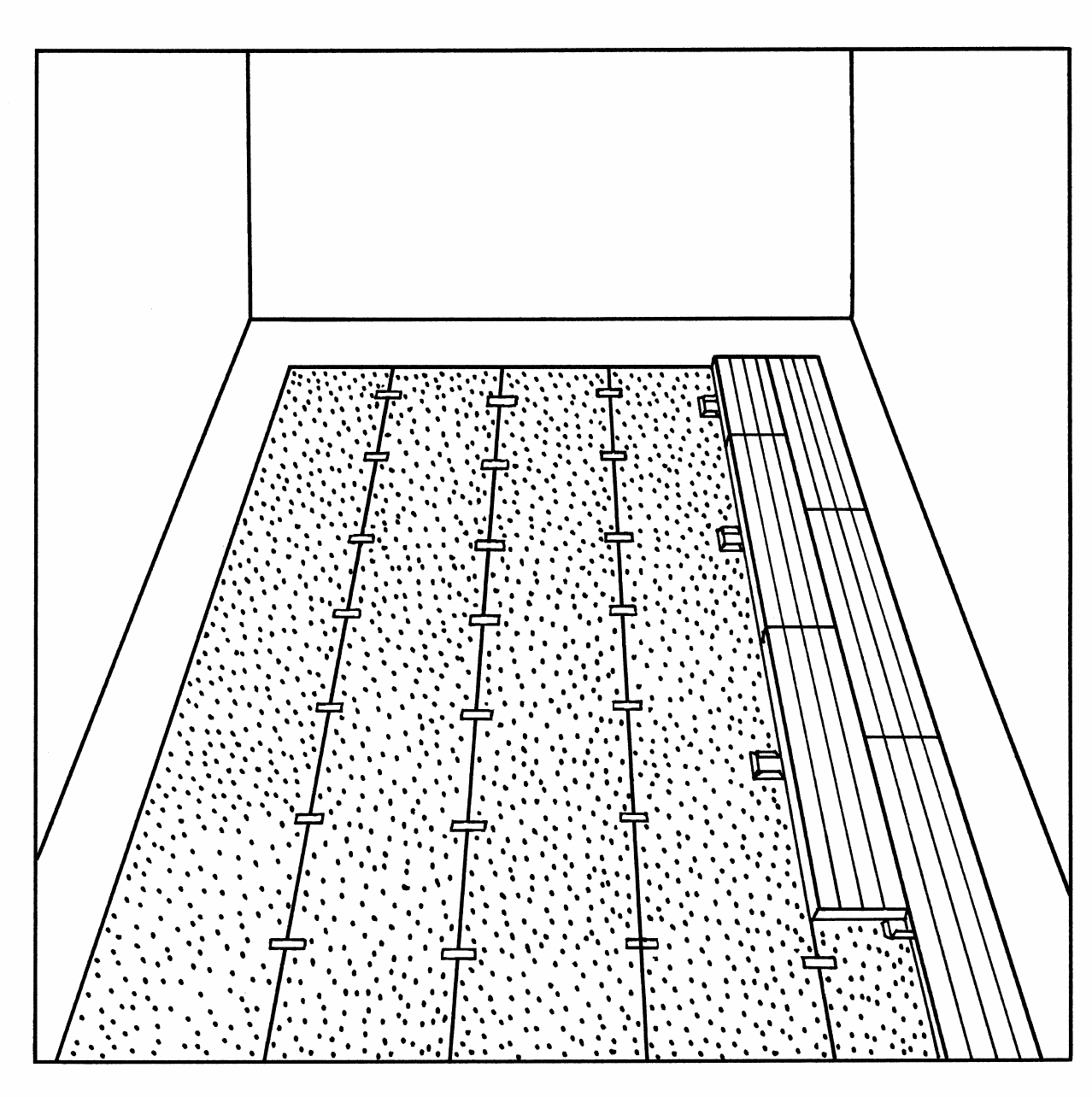

4. LAYING OF PORTABLE ELEMENTS

The elements are laid in an interlocking pattern so that all end joints are staggered 900 mm from row to row.

NB: The elements are pressed close together in lengthwise tongue and groove joints before they are pressed down into the assembly frame/fitting using e.g. a rubber hammer.

Elements without the assembly frame are used for the last row.

5. SKIRTING

If skirting is used it is mounted at the outer perimeter of the floor. Use a rubber hammer if necessary.

Start with the 8 corner profiles and then adjust the skirtings.

Make sure the skirtings are in correct position in order to support the elements (see small picture).

6. DISMANTLING OF PORTABLE ELEMENTS

Dismantle all the skirtings in the perimeter of the floor.

Remove loose joining tongues using the removal hook, and dismantle the elements row by row starting with the last installed element.

Carefully take up the elements and stack them in the transport carts. Space the individual elements to ensure optimum ventilation.

NB: Junckers transporters can store 40 elements per cart.